Variable Speed Pump Control Series

To control a variable speed pumping system, we must determine the minimum operational head of the system. Some refer to this value as constant head, minimum head, independent head, etc. Throughout this and in other JMP blogs, we refer to it as ...

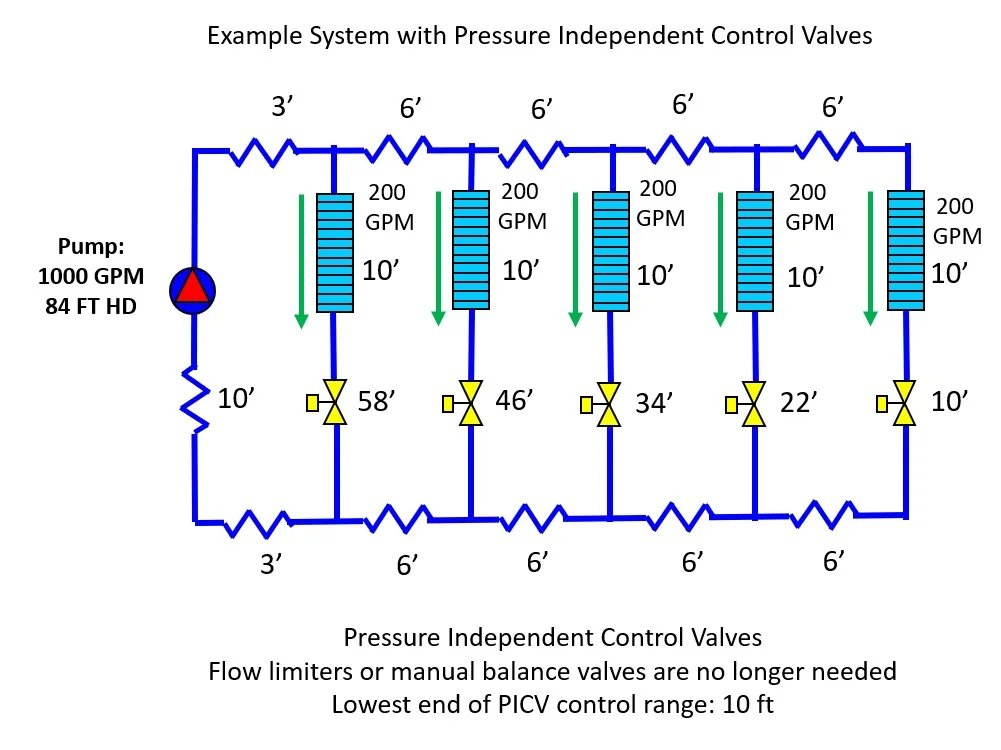

In our last blog, we cautioned against using pressure independent control (PIC) valves when attempting to apply area control with reset. But why is that a problem? Aren’t PIC valves the greatest thing since microwave ovens?...

What is the one piece of hardware in a hydronic system that distinguishes Variable Speed Curve Control from Variable Speed Area Control?...

We call him Mr. Creep.

Mr. Creep is not an actual person but rather a phenomenon of an ever-increasing control head in a variable speed pumping system caused by frequent incidents of underflowing coils, the result of which is progressive increases in operating cost and potential non-compliance....

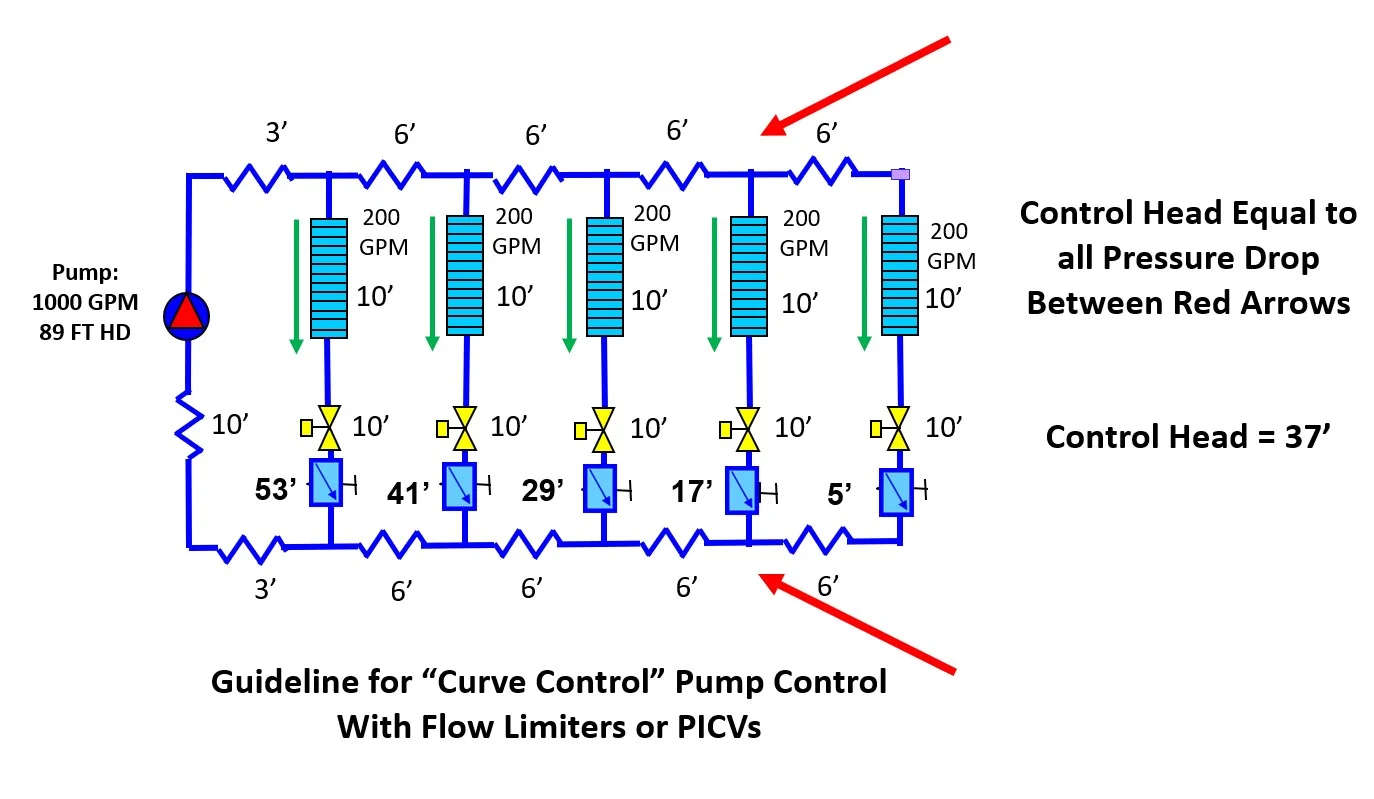

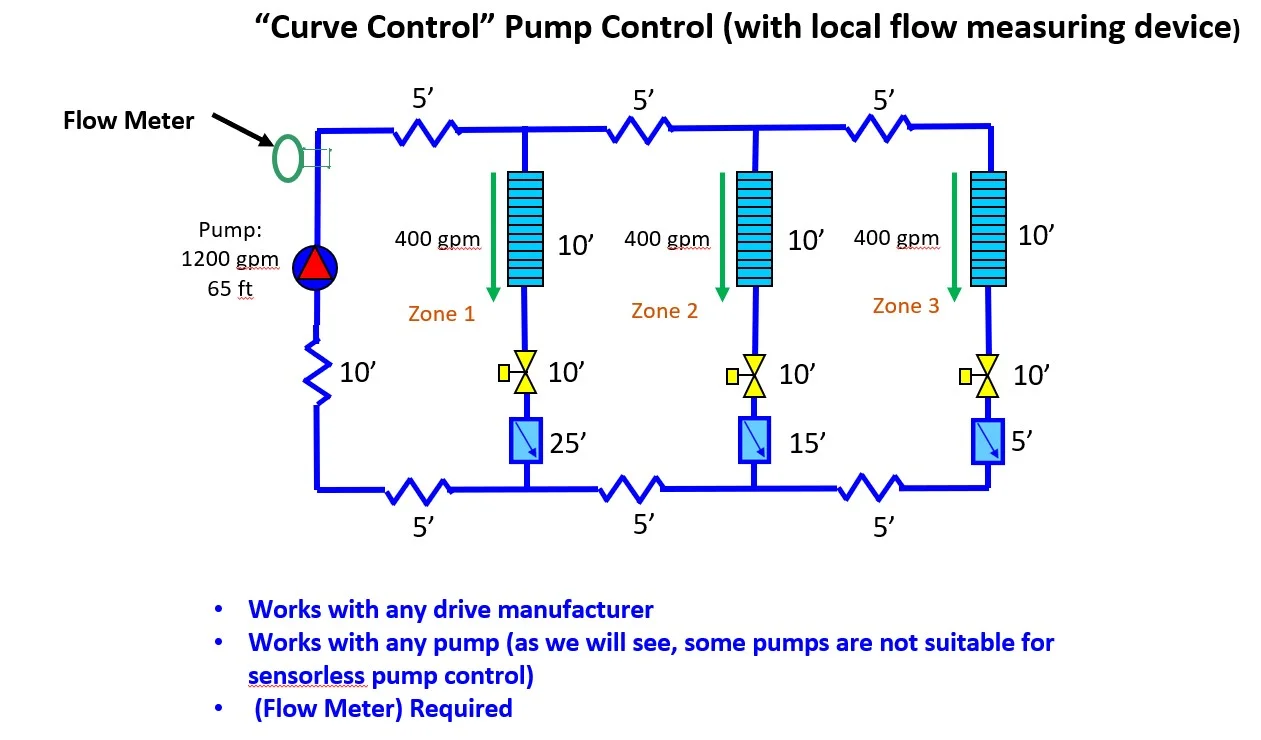

We’ve been talking about variable speed control since September 11, 2017, beginning with this blog ASHRAE 90.1-2010/2013: Impact on Variable Speed Pump Control in Chilled Water Systems. Throughout our coverage of this topic, we have introduced and re-introduced the concepts of “Curve Control” and “Area Control” as variable speed pumping control strategies, each time digging a little bit deeper. Today we are going to take an all-inclusive look at Curve Control, because we feel like the concept is often misunderstood .....

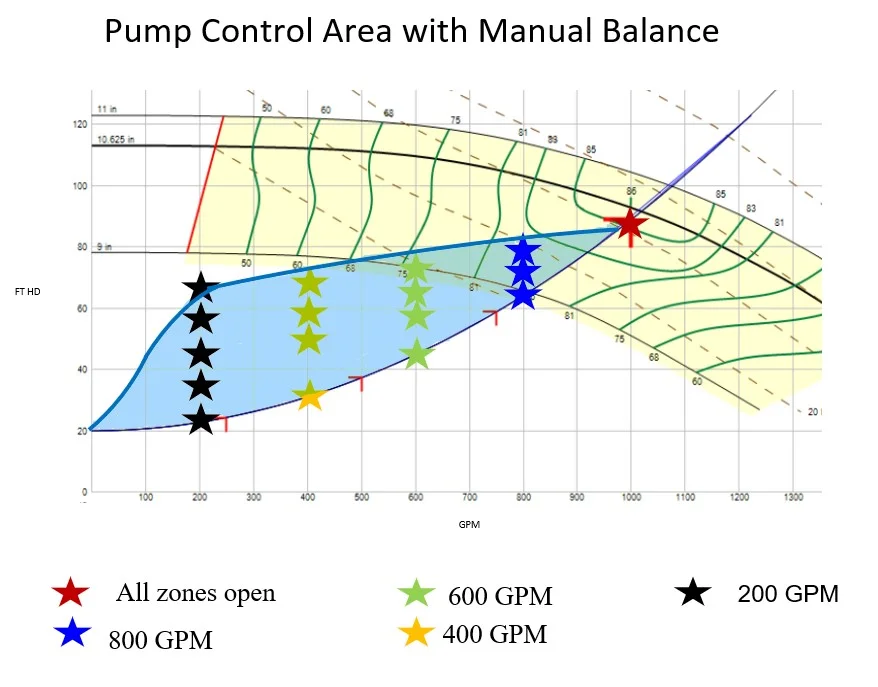

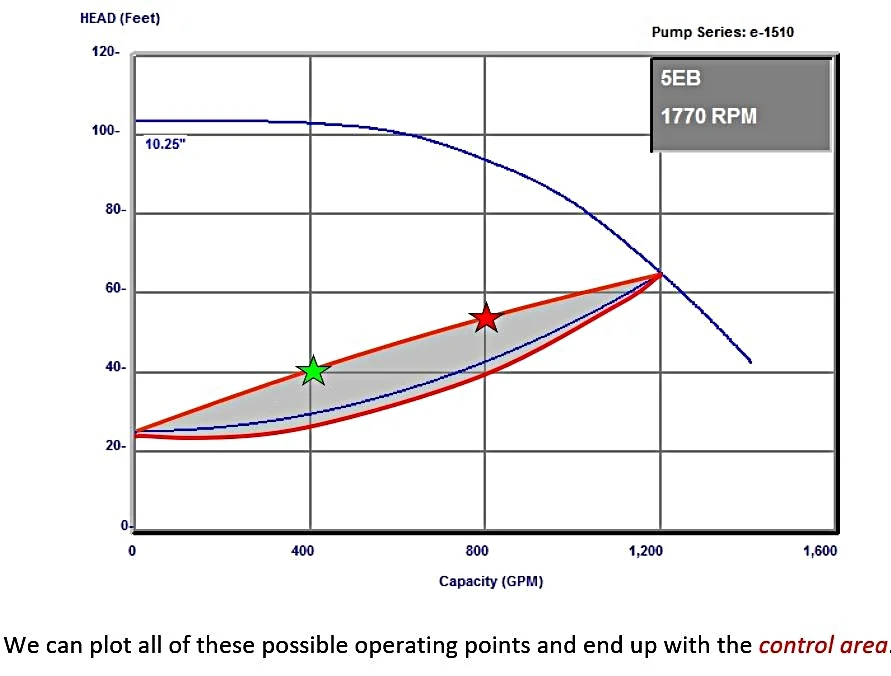

We’ve talked about manual versus automatic balancing methods and we’ve talked about curve control versus area control. Now it’s time to consider the balance valve type impact on the pump control area. Let’s start this conversation with a question...

Today’s flow balancing devices for variable flow pumping systems fall into three main types...

Last week we learned that ASHRAE defines a balanced system as one that delivers a flow sufficient to achieve a 97% heat transfer at each coil. This week will look at why we balance and outline the strategies that are ...

In our last blog we discussed how to leverage system diversity to maximize energy efficiency. Specifically, we learned that we can size heating or cooling capacity based on peak blog load rather than total connected load if the system is designed and operated correctly. Today, we will talk about flow tolerance and how ...

Comfort and efficiency are the ultimate goals of variable speed pump control. As technical as the discussions may become, it all comes back to comfort and efficiency. With that in mind, let’s review the concept of diversity, because managing system diversity enables us to...

In our last blog, we showed you what happens in a variable speed system when load drops. For clarity, we chose an unrealistically simple example of a system with only one coil. Today we’re going to give our system a small dose of reality by incorporating multiple zones...

What happens when demand drops in a closed loop variable speed system? What is the operational sequence and what logic does the controller use to vary the speed of the pump? Let’s begin our discussion with the following...

We are now three blogs into our series on Variable Speed Pump Control and we are going to hit the pause button and review some fundamentals. If sequentially that seems like a strange thing to do, there is a method to our madness...

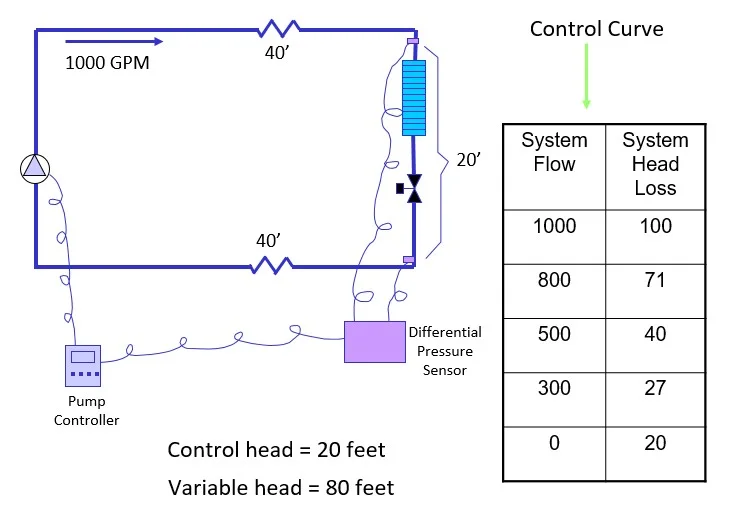

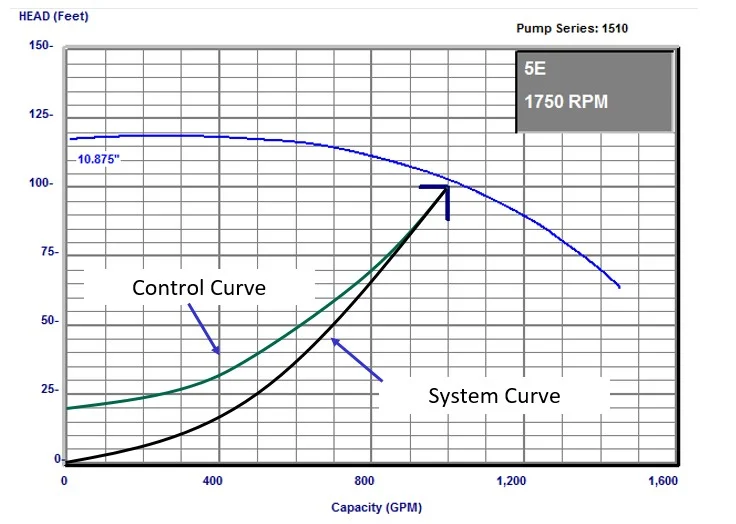

In our last blog, we left you with two new terms, “Control Curve” and “Control Area,” indicating that any variable speed control strategy will be based on one or the other. What are these strategies and how do they differ? Before we pull out the curves, schematics and calculations, let’s start with a simple analogy...

Today we begin a series of blogs exploring modern variable speed pump control. While we have written about variable speeding pumping in the past, we believe that the increasing presence of variable speed systems, along with the rapid evolution of control options, warrants a comprehensive look at variable speed pump control as a...

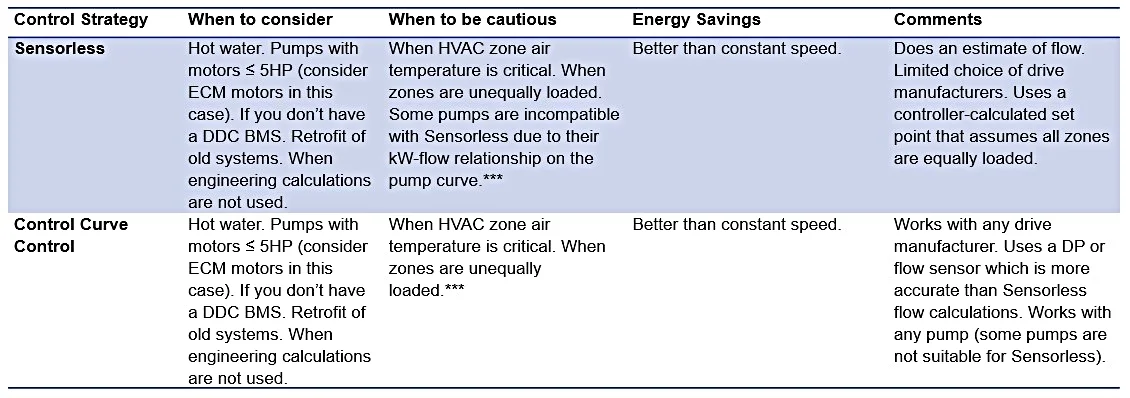

If this series on variable speed pump control has taught us anything it’s that there is no one-type-fits-all control solution. Control strategies must be applied based on the system design as well as ...