Parallel Pumping in Condenser Water Applications Series

Over the last few weeks we've looked at pumping issues with parallel equal sized condensers and pumps. This week we will look at the parallel condenser systems where the condensers are different types or sizes.

Chilled water condensers are normally operated as constant flow devices and the pumps serving them are constant speed. Why would you ever use a variable speed drive for a pump in this application? This week we show you a couple of reasons...

In Part 1 of this series we offered an example of a condenser water pumping system with 800 GPM per condenser for a total of 1600 GPM with the third condenser serving as standby. The tower elevation or lift is 10 feet, the condenser (with the 2-way valve and balance valve) has 20 feet of pressure drop, and the common piping with any safety factor has 30 feet of pressure drop. But there was a problem....

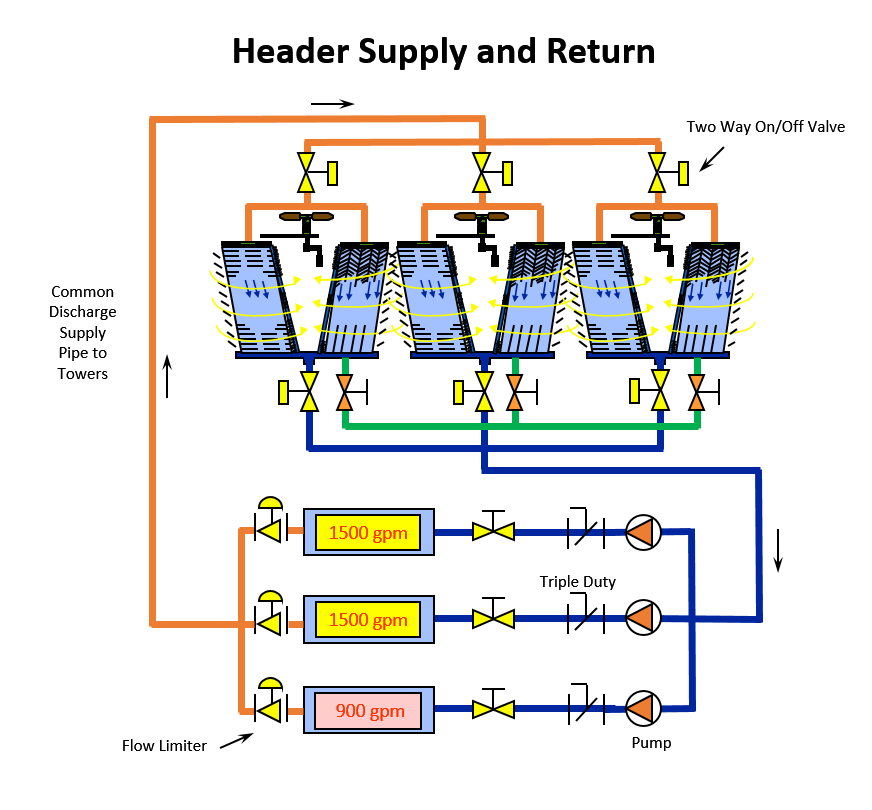

Applying a single constant speed pump for each condenser in a chilled water application is a normal design for the HVAC engineer. Some chiller manufacturers suggest piping the pumps with a common header and activating each pump as the condensers are staged on. However, there is a hidden issue with this approach, which, if not addressed may cause major problems....

Over the last few weeks the we’ve looked at pumping issues with multiple condensers and pumps. We have received questions about the topic, including these two:

Why do I need cooling tower outlet On-Off valves if I have an equalizing line?

Why do we see outlet On-Off valves on almost all jobs in North Carolina and only half the jobs in Michigan and Northern Ohio?