Steam

Every HVAC professional needs a basic working knowledge of the operating properties of steam. Although steam heated systems are not as common as they once were, many do still exist and must be maintained. Steam also plays a role in many modern domestic hot water and process applications. The articles below cover some the more relevant topics related to steam systems today.

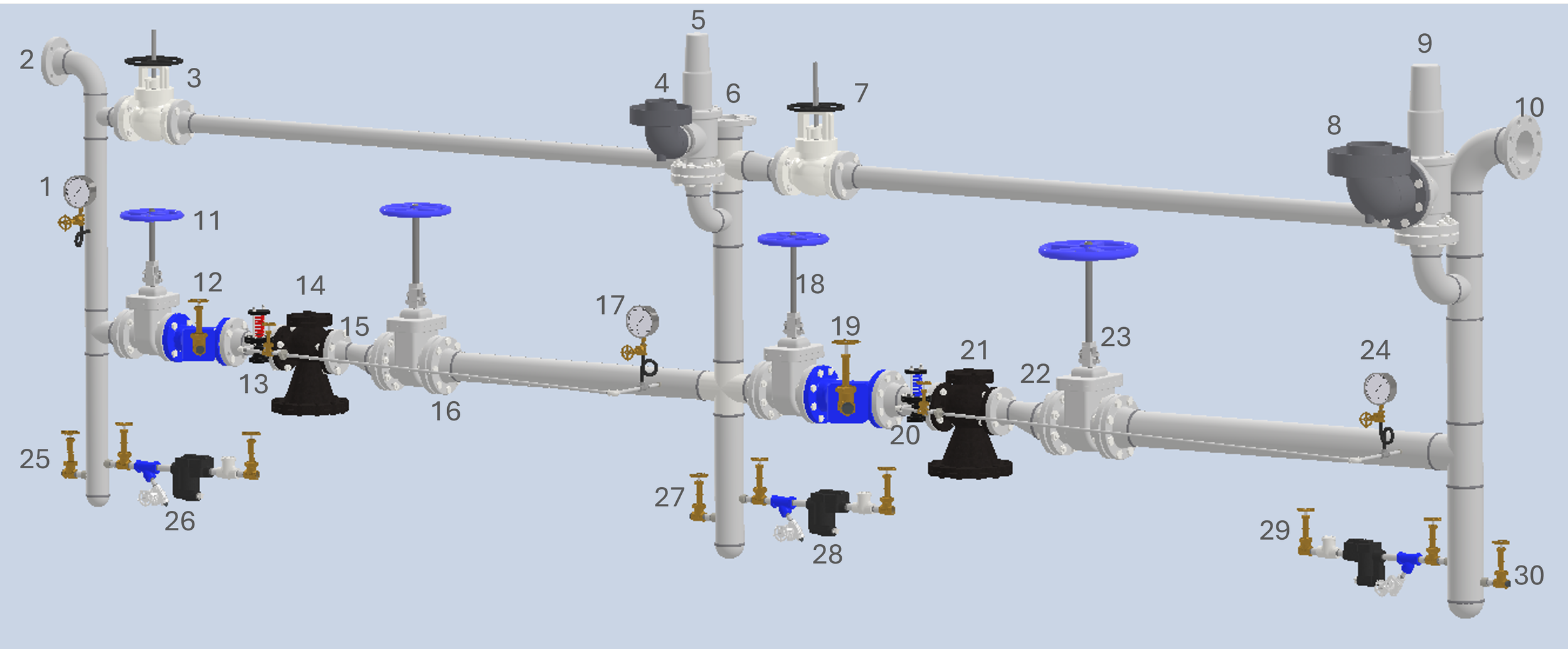

In our last blog post, we discussed pilot-operated steam PRVs in series. In this post, we’ll look at PRVs in series as an effective solution for systems that require multiple operating pressures or large pressure reductions. This article explains when and how to install PRVs in series, along with considerations….

Steam systems require precise pressure control to ensure efficiency, safety, and equipment longevity. Pilot-operated pressure reducing valves (PRVs) are widely used for their accuracy and stability under varying loads. When loads exceed….

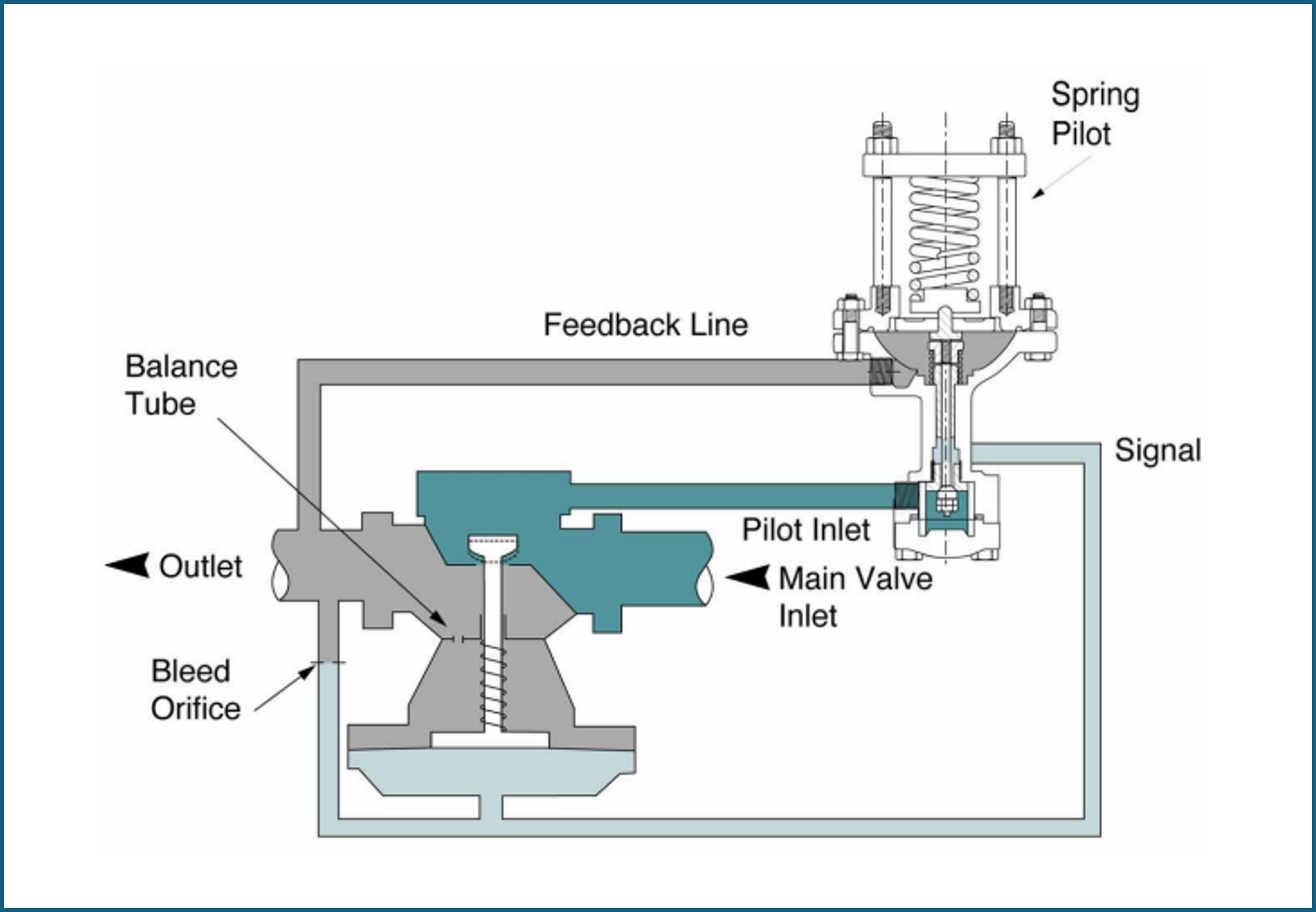

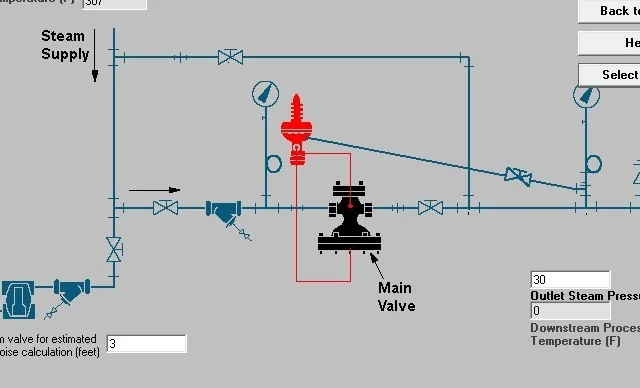

For precise and stable control of steam pressure, particularly under widely fluctuating loads, a pilot-operated pressure reducing valve (PRV) is superior to a simple direct-acting valve. The "brain" of this system is the spring pilot, which acts as….

Pilot operated steam pressure reducing valves (PRVs) offer superior performance compared to direct-acting regulators in systems with….

In our last blog article, we discussed the advantages of distributing steam at pressures that are likely higher than the ideal pressure for condensing steam in a heating system. This necessitates the use of pressure reducing valves to reduce the steam pressure to….

Our series on steam heating systems began with a review of the steam table. Now, let's examine how steam pressure selection affects processes in HVAC systems. Before we can use steam, it must be generated by a boiler. There are incremental fuel costs associated ….

Steam has been used for comfort and process heating for over a century. While it offers numerous advantages, a thorough understanding of its properties is essential for a successful application. In this series, we discuss steam properties and how…

In our last blog we described the difference between horizontal and vertical high-pressure condensate flash tanks. Once a decision is made between the horizontal and vertical orientation, the engineer must select the trim and show the installation detail...

The last several weeks we've focused on steam and condensate handling. Today we'll talk about steam flash tanks. Condensate flashes into steam in the return lines after the steam traps. When the steam pressure exceeds 15 PSIG and is defined as medium or high pressure, flash tanks are used to...

Last week we talked about the critical relationship between the steam condensate return temperature and proper pump NPSHR. This week we'll look at the role the discharge balance plays in assuring....

One challenge to selecting a steam condensate return unit is the return temperature of the condensate after leaving the steam heat exchanger. This week we'll offer some suggestions to assist the engineer or designer...

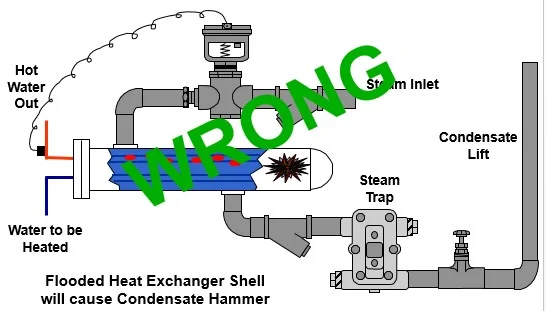

Hopefully, the message from our last blog on Steam Basics was clear: Don’t lift the condensate out of a steam heat exchanger or coil with a modulating control valve. So what do we do if a gravity return main is not located below the steam trap? We use a ..

Don’t lift the condensate out of a steam heat exchanger or coil with a modulating control valve! Over the last several weeks we have made this declaration several times. Once again, a voice in the wilderness has cried out....

Over the last few weeks we've examined the trap sizing out of a heat exchanger or coil with a modulating control valve. This week we turn our attention to the heat exchanger, or coil piping, after the steam trap. Often, the gravity condensate return main is installed overhead and there is a temptation to...

In continuation with our series on steam basics, today we want to take quick look at strainers and their application in steam systems. It may come as a surprise to some that...

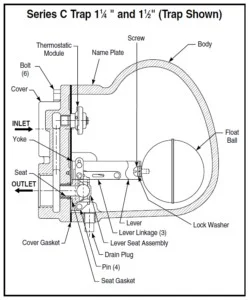

For the last two weeks, we have explored how the float and thermostatic steam trap operates, offering some tips for troubleshooting problems in the field. This week we will select a trap for...

Steam traps play a very important role in steam systems. Last week, we discussed how the float portion of a float and thermostatic (F&T) steam trap operates. This week, we will explore the operation of...

When discussing steam heating and steam heat exchanger basics, an important component for proper operation is the steam trap. At times, it feels like steam trap selection and sizing is more of an art than a science...

In this installment of our Steam Basics Series we will explore the steps for sizing the steam pipe and the pressure reducing valves using a health care office as an example. In this case, let's say the engineer is designing....

Today’s HVAC and process engineers have lots of choices when it comes to pipe sizing programs for steam and condensate applications. Put in a load and a pressure and out pops the answer. But ever wonder about how that answer is generated? Or if there are times when it might be suitable to choose another pipe size....?

When using a sizing program to select steam pipe sizes, the engineer or contractor is asked to fill in the capacity, the steam pressure, and the velocity required. The answer is ....

A few weeks ago we discussed the steam pipe size entering a shell and tube heat exchanger, also called a convertor. This week we turn our attention to the condensate outlet. A customer recently asked, “I was told to pipe a 14-inch condensate drop leg from the bottom of a steam-to-water heat exchanger to the F&T trap inlet. What happens if I ...?”

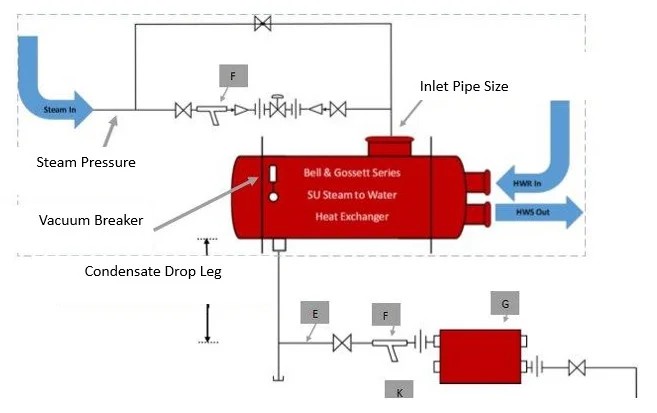

This week we take a look at the vacuum breaker on a steam-to-water heat exchanger. Steam-to-water heat exchangers, or steam heating coils with on-off or modulating control valves, require a vacuum breaker. This simple and relatively inexpensive device may save ...

Why do you tend to use low-pressure steam in HVAC and domestic water heat exchanger selections? When selecting a heat exchanger, the diameter is determined by the design flow rate and ...

Many institutional and industrial projects use steam to heat the water for hydronic heating, domestic water, or processes. The pipe size prior to the steam control valve is often shown, but the pipe size from the control valve to the steam-to-water heat exchanger or converter is rarely shown. A question we receive often is...

Steam heating systems are a bit of a mystery for many engineers and contractors. Much of the “old school” knowledge on steam heat exchangers retired years ago. With the limited number of new steam systems being installed today, this subject is rarely covered with any detail. Most healthcare facilities and some industrial facilities use ...

By Jerry Timm

When the laws and characteristics of steam are respected, fewer operating problems occur and unnecessary costs are minimized.

Four Types of Steam

Steam is an invisible gas created by adding heat energy to water. It is liquid water changed to its gaseous state.

By Mike Sneary

Superheated steam occurs when heat energy is added to saturated steam that is not in contact with liquid. When the heat energy is added, the steam temperature is increased above the saturation temperature. Superheated steam is referred to as ‘dry’ steam meaning it contains no water droplets. This effect can also occur when the pressure of saturated steam is reduced through a pressure control valve.

In our final brief blog post on pilot operated steam PRVs, we consider systems that have a large pressure drop, highly variable loads and require steam at an intermediate pressure. A parallel-series PRV station….