Cooling Tower and Condenser Water Design Series

Featured

Cooling Tower and Condenser Water Design Part 11: Avoiding Common Pitfalls

We thought it would be a good idea to review some of the most common pitfalls in cooling tower/condenser water design and how to avoid them. We see these so often and the consequences can be so profound that each bears a final warning. Take care to avoid these scenarios and we promise that everyone (from your equipment suppliers to your chemical treatment specialist) will be much happier.

Most commercial HVAC professionals are probably already aware that there are two different types of cooling towers – crossflow and counterflow. While both operate on the principle of evaporative cooling by blowing air across water, the physical configuration of these two types of cooling towers differs quite a bit. Read more....

Successful cooling tower operation and performance involves a delicate balance between (1) keeping the dissolved solids (such as calcium, magnesium, chloride, and silica) in the water from causing too much scale and/or corrosion and (2) conserving make-up water. It’s expensive, inefficient, and environmentally irresponsible to continuously dilute cooling tower water with an abundance of make-up water just to keep the ratio of minerals down. But how do you decide how much make-up water is needed to keep minerals within a tolerable range?

Correctly piping the suction and discharge of your cooling tower/condenser water pump is critical. Some fairly catastrophic events can occur if either is improperly installed. Here are some best practices for piping cooling tower/condenser water systems....

Want to make sure the cooling towers in the systems you design operate as intended? If you are a design engineer, you are responsible for outlining the staging sequences of the cooling tower systems you design. This means putting together a list of the acceptable operational sequences, outlining what every piece of equipment will be doing at each and every stage.

Here's how you develop that list which the controls vendor will use to program the system...

Larger facilities often have multiple cooling towers serving multiple chillers, enabling them to more closely match demand. Piping such systems can be a challenge, depending on the amount of flexibility desired. Here we describe the three most common approaches to piping multiple cooling towers and chillers.

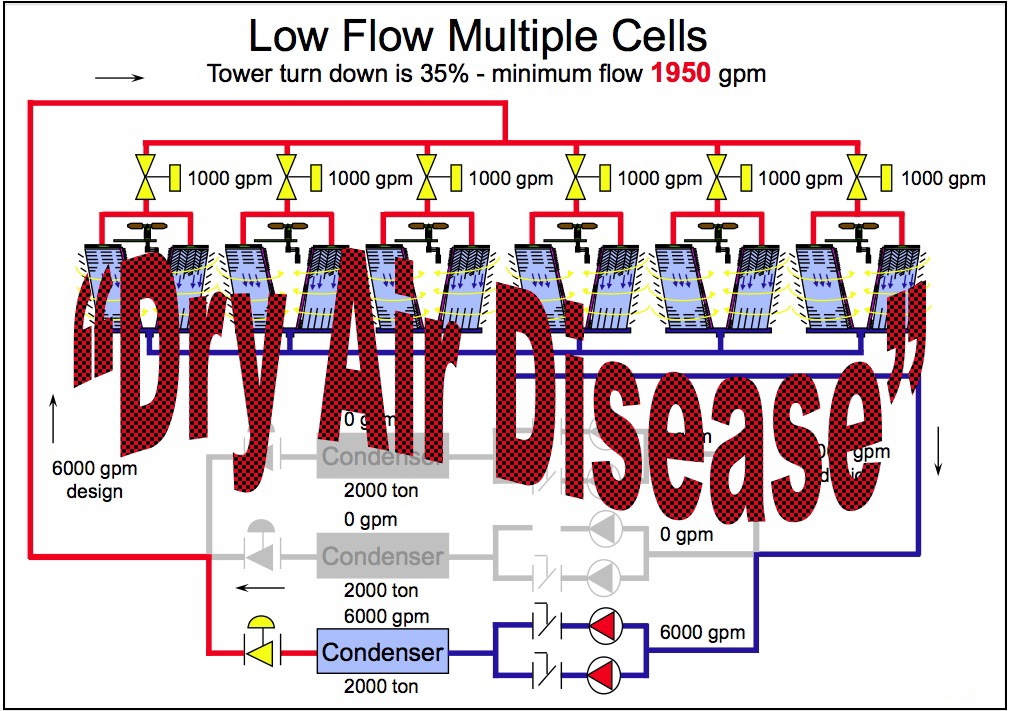

We like to vary flow through our hydronic systems, don’t we? After all, less flow equals less pump energy. But when it comes to cooling tower performance and longevity, just be careful not to overflow or underflow the tower. Either scenario can lead to some pretty costly problems.

Cooling towers are one of the most effective strategies for reduction of cooling load – at least as long as you don’t invade their personal space. Cooling towers are far more likely to do their thing and do it well when they’ve got some room to breathe, preferably with an unobstructed view. Bad things happen when you crowd a cooling tower with walls or solid enclosures....

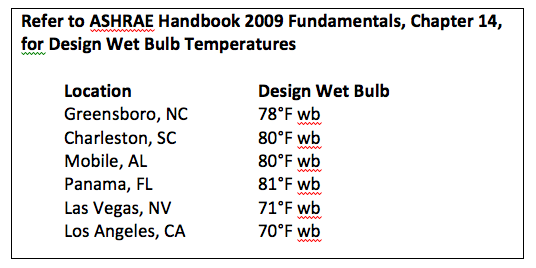

Last time we talked about the impact that the wet bulb temperature has on cooling tower performance. In summary, it’s harder to evaporate water into air that’s already wet. (I.e. The higher the wet bulb, the harder a cooling tower has to work to evaporate enough water to maintain set points.) In this blog, we’re going to define what those set points are, how cooling towers are rated, and finally how these factors impact the cooling tower size and operation for a given application.

Cooling Tower and Condenser Water Design Part 2: The Impact of Wet Bulb on Cooling Tower Performance

How do you evaluate the performance of a cooling tower? What factors impact how effective a cooling tower will be in a given application? To get to the bottom of either of these questions – which are essential questions to ask when sizing a cooling tower – it’s important to understand the impact of the ambient wet bulb temperature on cooling tower performance.

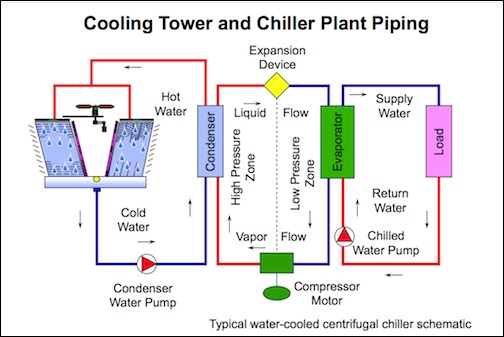

Cooling towers are simple mechanisms. Their operation is based on the natural occurrence of evaporative cooling – something most of us have experienced daily since the first time we got wet and felt a chill. But despite their simplicity, cooling towers play a crucial role in operational efficiency of the entire chilled water system. Not only are they the exit point for all those BTUs in a building that the chilled water system is working so hard to absorb and eliminate, their operation has the potential to significantly reduce the amount kWs going to the biggest energy hog in our system—the chiller.