Steam Basics Part 17: Condensate Pump Discharge Balance Valves

/By Chad Edmondson (JMP) and Norman Hall (RLD)

In our last blog we focused on the critical relationship between the steam condensate return temperature and proper pump NPSH required for trouble-free operation. This week, we'll look at the role the discharge balance valve plays in assuring long life in these pumps.

The required NPSH of a pump varies with the flow through the pump. The flow is based on the system capacity and the receiver size selected. The pump head is normally expressed in PSIG and is the combination of friction loss, elevation or lift, maximum back pressure in the return header into which it is being pumped, and a safety factor, which includes some pipe corrosion allowance. When the pump is commissioned for a given flow rate, the friction loss is constant and the lift up to the main or tank is constant. The variability lies the back pressure and corrosion of the pipe over time. Why does this make a difference?

Condensate Pump Operation is Different than most Hydronic Pumps

The system curve for condensate pumps is much flatter than in most hydronic systems. Let’s use an example to illustrate this.

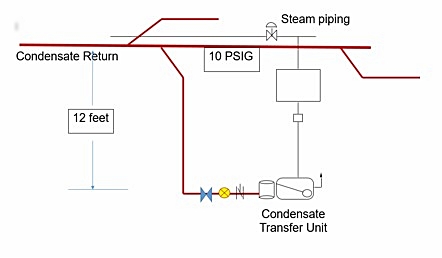

In the example below, we assume the friction loss at 90 GPM is 14.5 feet or 6 PSIG. The elevation is shown as 12 feet or 5 PSIG. The engineer determined that the back pressure in the common return main could be 10 PSIG and the safety factor used is 5 PSIG. The pump will be selected for 90 GPM at 26 PSIG or 63 feet. Most condensate pump selections would round the number up to the nearest 5 PSIG but will assume the head is 63 feet.

The pump curve shown below requires only 2 foot NPSH at 90 GPM. The more expensive 2’ NPSH pump was selected due to the 209°F return temperature expected. The 4.25” impeller would be used for our 63 feet of head. What happens when we start the pump? The safety factor and corrosion do not exist. The actual operation point would be at point 2, or about 110 GPM. The pump would require 4 feet of NPSH and would cavitate at temperatures above 206°F. The discharge balance valve MUST be throttled to impose more head and get the operation to 90 GPM at 63’ head.

Does your balance valve specification call for the balancer to adjust the condensate pump flow rate?

The Hidden Problem & Solution

There is another issue. What happens when the 10 PSIG back pressure is not there? The pump will operate at point 3 some of the time. This will result in cavitation and the pump running off its curve. This pump will destroy itself unless we use a flow limiting balance valve. Now the valve is set to 90 GPM and opens and closes as pressures change in the system.

The solution is to install the flow limiting Bell and Gossett series AC or WV automatic flow limiter valve, depending on pipe size. Now it is automatically balanced. Simply add the following line to your Bell and Gossett Domestic brand condensate and boiler feed unit specification: “For each pump, manufacturer shall provide a Bell and Gossett series AC flow limiting balance valve for pipe through 2-1/2” and a Bell and Gossett series WV wafer style flow limiting balance valve for sizes 3” and over. Valve shall be preset to the GPM of the scheduled condensate return pumps.”

Flow limiting balance valves.

Proper condensate handling, proper pump selection, and proper installation together assure an excellent operating system.

Pump seal limitations for condensate pumps such as the Domestic CC, CB, and CBE style units are rated for 250°F. Since the receiver is vented, there is no concern about seal temperature for these Domestic models. However, there is concern that the pressure available at the pump suction will be able to keep this high-temperature water from flashing into steam. In general, the condensate pumps must have a low required net positive suction head (NPSHR) to handle the low pressure higher temperature condensate.

We recommend you read the Bell & Gossett article about NPSH and pump seals for more details.

Condensate, Flash Steam, and Air

When the condensate from the heat exchanger passes through the Float and Thermostatic (F&T) trap to a vented dry condensate return, we know a percentage will flash to steam. This was mentioned in a previous blog. The dry return pipe was filled with air prior to the steam trap opening. Once the trap opens there is a mixture of condensate, flash steam, and air. The fact that there is a percentage of air mixing with the flash steam will result in a significant drop in temperature. There is also a BTUH loss through the pipe to atmosphere. Both of these act to reduce the water temperature before it enters the condensate unit.

The exact pump type required for the project may require specific information about the system; however, here are some general rules:

- If the steam pressure to the heat exchanger is less than 10 PSIG use a Bell & Gossett Domestic series CC condensate unit rated for return temperatures between 200°F and 209°F.

- If the steam pressure to the heat exchanger is over 10 PSIG but less than 20 PSIG use a Bell & Gossett Domestic series CB condensate unit rated 2’ NPSH for 210°F condensate.

- If the steam pressure to the heat exchanger control valve is over 20 PSIG use a Bell & Gossett Domestic series CBE (Elevated) condensate return unit rated 2’ NPSH for 212°F condensate. This may also be an excellent application for a Kadant Johnson Liqui-Mover® pressure powered pumping unit sometimes called a pumping trap.

Obviously, steam traps must be in good working condition and not leaking steam into the condensate system. In all cases remember if the condensate lifts into the receiver it must not lift above the heat exchanger steam trap.