Hydronic Balancing Part 12: Pressure Independent Control Valves

/By Chad Edmondson

If you’ve stayed with us throughout this entire Hydronic Balancing Series, you’re probably saying to yourself, “Does it really have to be that complicated?”

Fortunately, it does not. Designing, installing and balancing hydronic system became infinitely easier with the introduction of a handy little gadget called a pressure independent control valve or “PIC” valve. These valves, which first hit the market nearly two decades ago, have revolutionized hydronic balancing and are now quite common in newly designed central chilled water systems. (Plenty of older systems without PIC valves still exist, so keep our previous blogs bookmarked!)

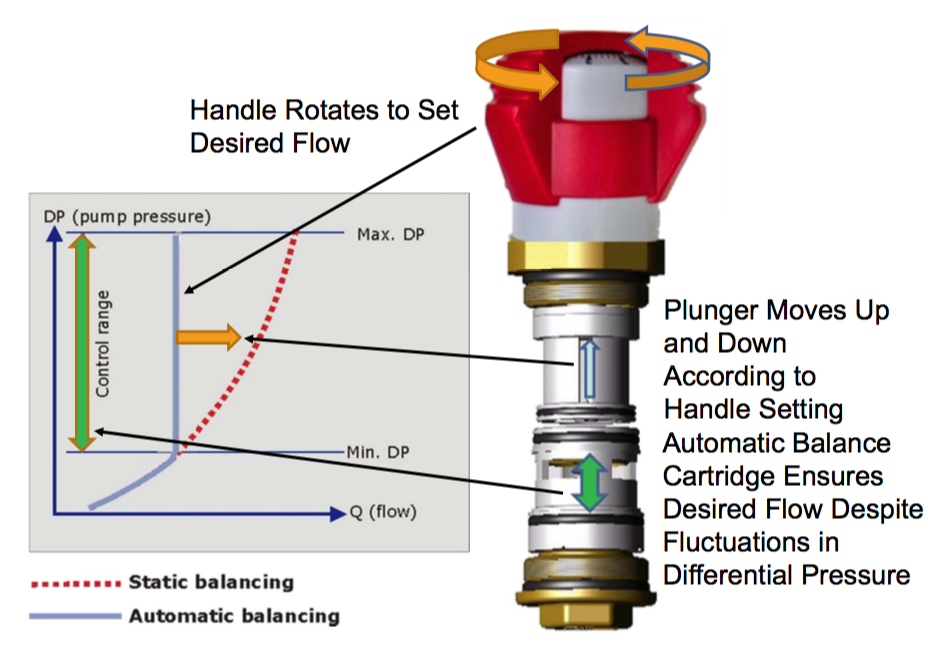

PIC valves are often described as two valves in one, a 2-way valve and a flow limiter. This is true, but it is the constant differential pressure that a PIC valve maintains across the 2-way valve component that differentiates it from conventional control with a 2-way valve and flow limiter.

How PIC Valves Work

PIC valves incorporate a spring loaded differential pressure regulator, which constantly adjusts and compensates for fluctuations in system pressure. This internal element responds to pressure changes by moving up or down, to maintain a constant flow despite these fluctuations.

PIC valves do not merely limit flow; they keep flow within a specific range. This eliminates underflows and overflows through the coil and ensures a much more consistent energy transfer.

There are actuated and manual PIC valves. Manual PIC valves have an external dial calibrated in GPM, which allows users to set the valve to the desired flow. These manual PIC valves are selected solely on line size and flow rate, eliminating the painstaking Cv calculations necessary for truly accurate balancing with conventional 2-way valves.

Because PIC valves automatically adjust themselves, they needn’t be re-adjusted after a chilled water expansion or renovation like conventional 2-way valves should be. This is another major advantage to PIC valves over traditionally balanced systems.

How PIC Valves Save Money

Technology always comes with a price, and certainly PIC are more expensive than 2-way valves and flow limiters. Some of this cost is offset by the reduction in piping labor. But the real value in PIC valves is in the lifelong system efficiency that they help ensure.

To fully appreciate this fact, one must consider the constant variances of pressure that occur in a typical chilled water system and the degree to which those variances impact energy consumption.

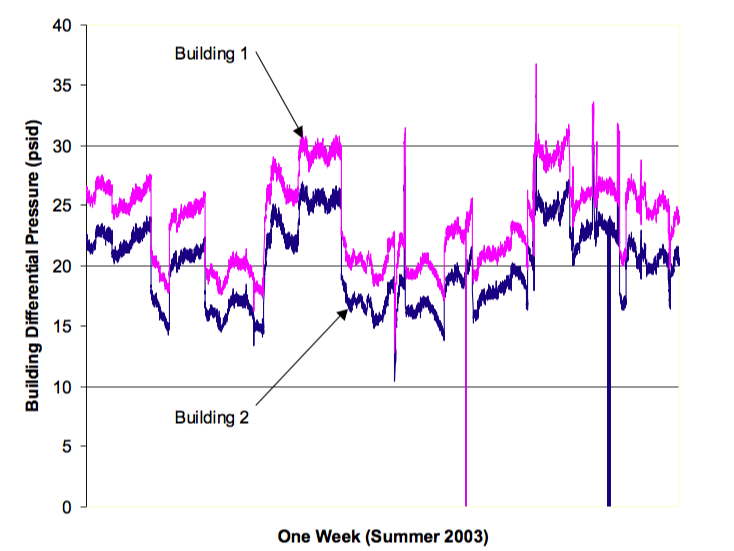

The graph below shows the real time pressure fluctuations in an actual chilled water system recorded over the course of a week.

As you can see, the pressures in a typical chilled water system constantly change. These changes are the result of variations in cooling load, opening and closing of valves to meet demand, and changes in pump speed or operation, etc.

Minor changes in pressure result in not-so-minor variances in flow, which translates into significant increased energy consumption. We know this for a fact because of the flow energy equation:

Q (Energy) = 500 x f x Delta T (in F)

Where,

Q = rate of heat transfer (Btu/hr.)

f= flow rate (gallons per minute or gpm)

Delta T = temperature change (degrees F)

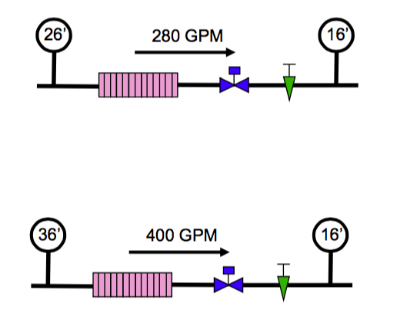

So let’s observe what happens when we increase the differential pressure on a 2-way control valve where the coil is sized for 500 GPM maximum flow:

If we increase the inlet pressure on the coil from 26’ to 36’ as shown in the example above, we automatically increase the flow from 280 GPM to 400 GPM. Note that this change is simply the result of common pressure fluctuations in the system – not changes in load. The position of the two-way valve has not changed. So flow has increased, as has the pressure drop across the across the coil and 2-way valve. The Delta T, however, has decreased. We’re not transferring any more energy at 400 GPM than we were at 280 GPM.

Thus even a small change in pressure, the kind that happens every day in large systems, has a major impact on system efficiency. The only way to combat this inefficiency in a conventionally balanced system is to meticulously select each and valve in the system. This can be a daunting task if you have a thousand or so valves. Furthermore it’s a task that probably should be repeated each and every time the system is expanded or modified.

PIC valves eliminate all of these headaches, as well as the energy losses that come with constantly fluctuating system pressures!