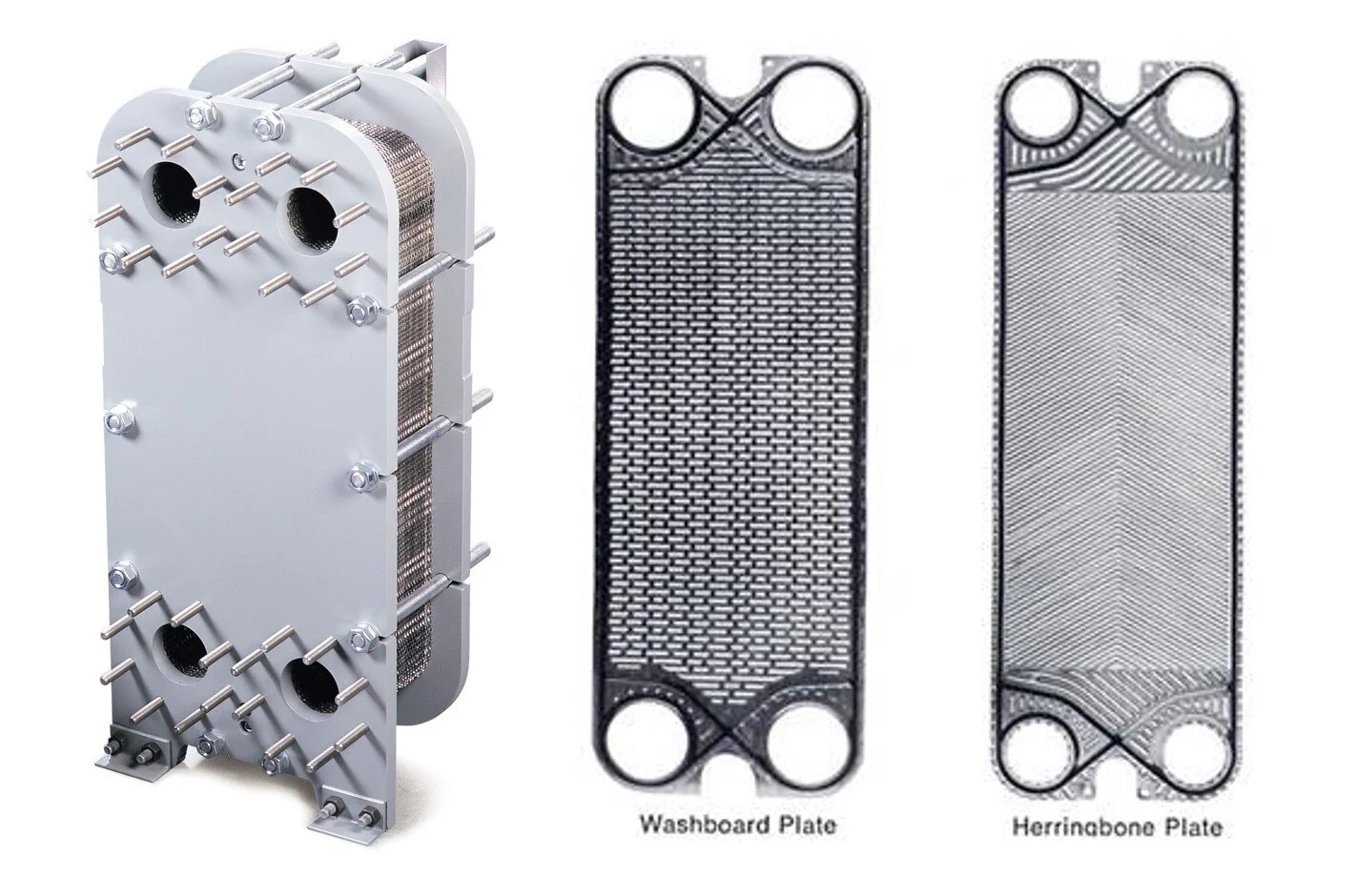

How To Size A Waterside Economizer Part 5: Why Plate & Frame Heat Exchangers Are Preferred

/Waterside economizing typically involves the transfer of BTUs from an open loop cooling tower system to a closed loop chilled water system. Since these two hydronic systems must remain separate so we do not foul the chilled water systems, a heat exchanger is required to prevent mixing of the fluids, but what type of heat exchanger should you choose?

Read More