WSHP System Design Part 4: Water Side Components and Considerations

/By Chad Edmondson

What components make up the water side of a WSHP design besides the heat pumps themselves? And what “best practices” should engineers observe to optimize the efficiency and longevity of water side equipment?

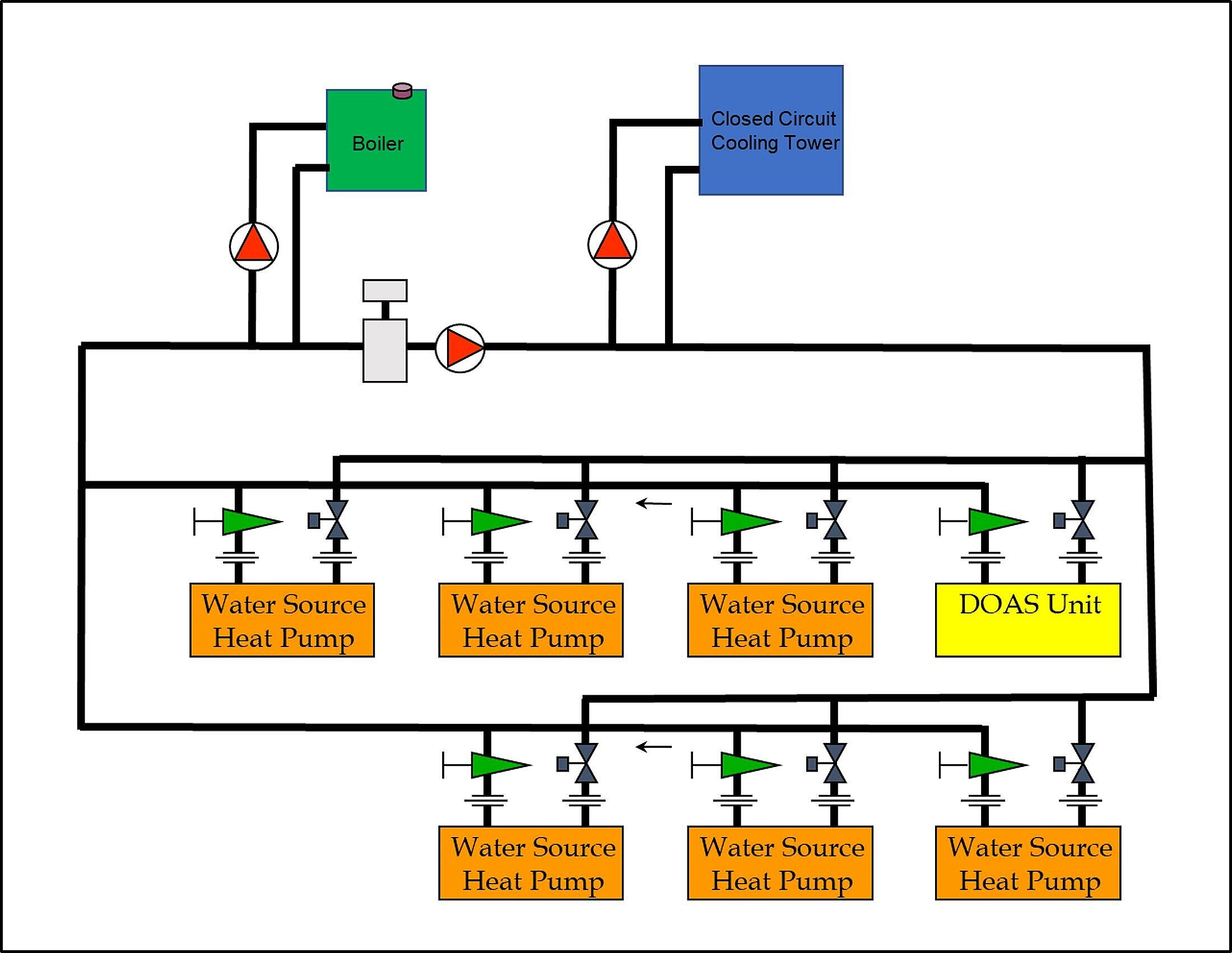

The water side of a multi-zone WSHP system is thankfully very basic. In addition to the piping, there are only three major components:

1. A cooling tower for rejecting heat during the cooling season

2. A boiler for adding heat to the circulating water during the heating season

3. Pumps to serve the boiler, cooling tower and system

There is no chiller or condenser water loop. And since a WSHP system is always “redistributing” BTUs as needed and each WSHP unit contains its own refrigeration cycle, the boiler and cooling tower never have to operate simultaneously, even if there is a simultaneous demand for heating and cooling.

Cooling Tower Considerations

Open or closed cooling towers may be used in a WSHP system, although we recommend a closed circuit cooling tower (CCCT) for a few reasons. First, CCCTs have their own internal heat exchanger so there is no need to specify or find space for a separate one. This will also reduce the amount of space required in the building. Second, CCCTs provide for a closed loop system to protect the WSHPs from environmental debris and corrosion, which improves longevity and energy costs. Also, CCCTs may have a lower first cost because of a reduction in pumping requirements, floor space and added filtration that might be needed to keep a separate heat exchanger from fouling. CCCTs can even be installed inside the building if the owner wants to keep the equipment hidden. (Figure 1)

FIGURE 1. Closed loop cooling towers are recommended for WSHP system applications.

If, for whatever reason, an open tower is chosen, it is absolutely necessary to select a separate heat exchanger for installation between the system loop and the cooling tower loop. A WSHP system must be installed in a closed loop. We recommend an enhanced high turbulence shell & tube heat exchanger for this application because they are less susceptible to fouling and easier to service than plate & frame heat exchangers while still providing a close temperature approach.

Boilers (Preferably Condensing) Are a Must!

A boiler should be used as the heat source in a WSHP application, fulfilling the role that the earth would play in a geothermal heat pump system. Hydronic heat from boilers allows the owner to capitalize on BTU sharing of the WSHP system. A decoupled heating strategy like electric strip heaters for space heating would completely defeat the purpose of having a WSHP system. Gas-fired condensing boilers offer optimal efficiency, however electric boilers can also be used if gas utility is not available, or if the owner simply prefers electric or requires it to meet new carbon emissions reduction guidelines.

Pumps & VFDs

Finally, the engineer must decide what types of pumps to use – inline or base mounted end-suction. For ease of maintenance, we recommend base-mounted pumps with a center drop-out spacer coupler. This allows easy removal of the bearing frame and rotating element without disturbing the pump end pipe alignment or motor electrical components. Each pump should also be equipped with variable frequency drives (VFDs) to lower pump speed when demand is low.

Want to REALLY Shortcut Your WSHP System Design Process?

Instead of selecting each and every component for the “energy” portion of your WSHP system, you can choose a factory engineered and assembled package that includes boilers air separators, pumps, controls, and even a closed circuit cooling tower all pre-piped and mounted on a single skid. These “Water-Source Heat Pump Energy Plants” come complete with all the necessary wiring and supply and return connections.