Best Practices for Hydronic Systems Part 7: Pump Pad and Grouting

/Base-mounted pumps must have a solid foundation to prevent vibration and misalignment that can transmit noise and damage the pumps bearing, coupler and shaft. The manufacturer’s instructions for building this foundation and installing the pump are included in the installation and operation manual (IOM) and should be followed to avoid voiding any warranties. While these instructions may vary slightly from one manufacturer to the next, most if not all, require building and attaching the pump to a concrete base, as well as grouting the pump frame. In this blog, we will explain the purpose and installation process for both.

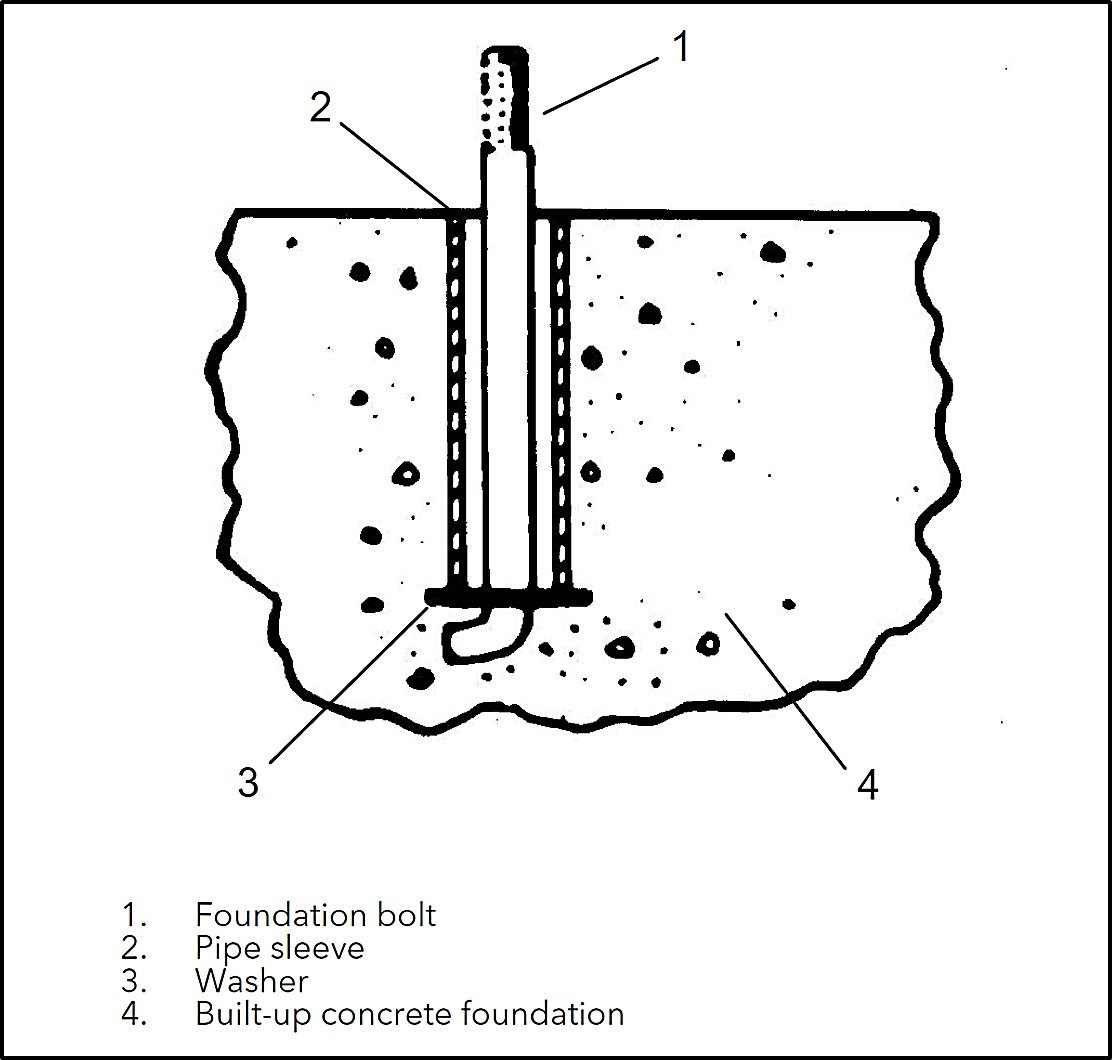

Figure 1

Building the Pump Foundation

Frame-mounted end-suction or split-case pumps should not be installed directly on the floor. For proper alignment and stabilization during operation, the pump needs to be installed on a poured concrete “pad” or “foundation” that meets the mass requirements as stated in the IOM. Bell and Gossett, for example, recommends that the foundation weigh at least 2-1/2 times the weight of the pump to prevent vibration. It must also be at least two inches larger than the pump base in length and width. Sleeve-type or J-type foundation bolts are typically used to attach the pump and frame to the pad. (See Figure 1.)

The pad needs to be permanently “tied” to the floor before installing the pump. Tying the base to the floor typically involves some combination of grout, rebar, and anchors to meet seismic codes and manufacturer’s requirements. By tying the pad to the floor, you can include the weight of the floor as part of the required mass of the pad.

If the pump is to be installed on an above-grade floor, you should consider using a spring isolated concrete inertia base, which is a steel frame around the pump base that includes vertical springs with concrete to provide vibration and movement control. If an inertia base is used, you also need to include spring hangers for the supply and return of the pump.

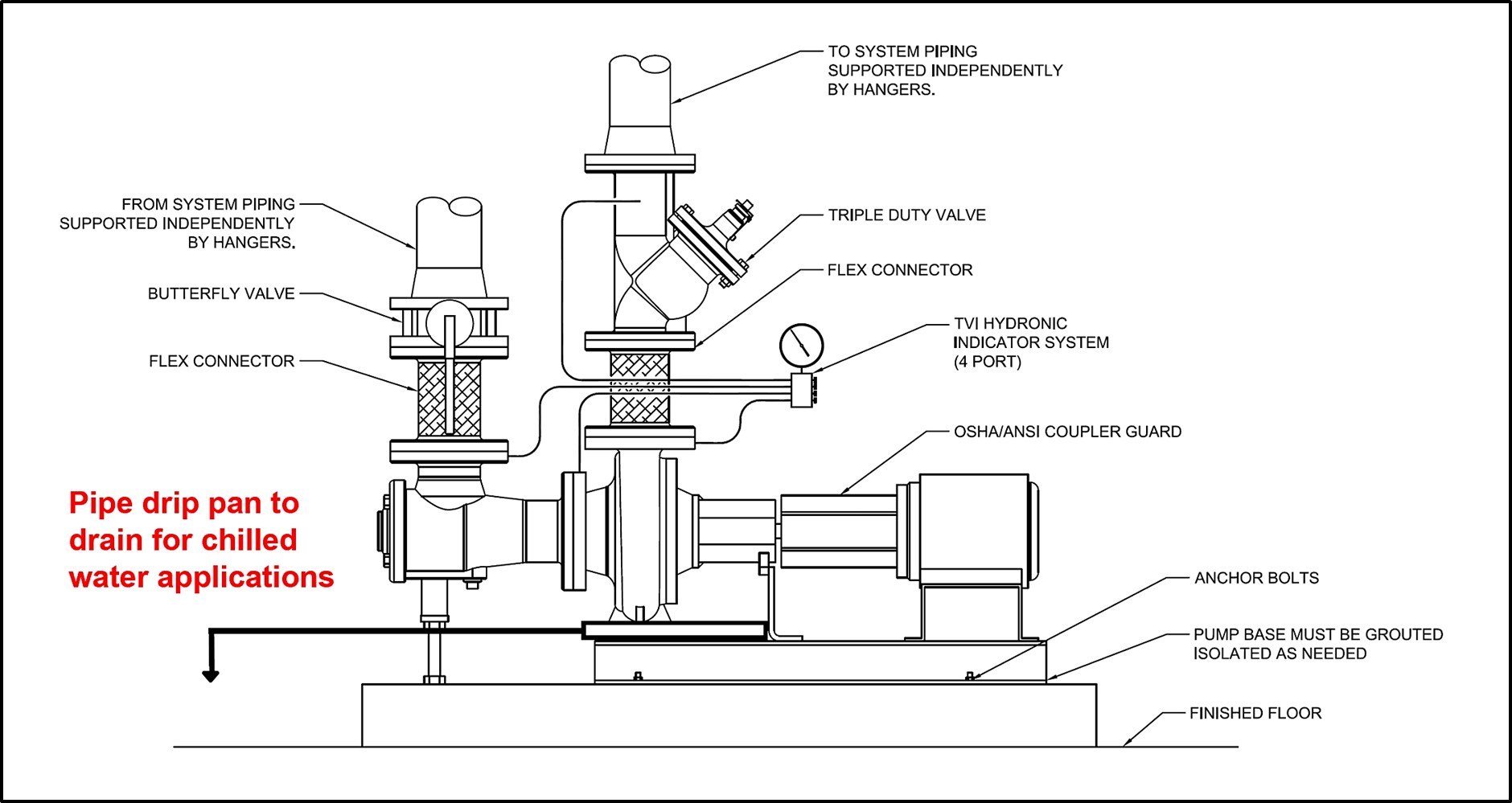

When using a spring isolated inertial base the header piping should be supported independently from the pump. We recommend that the first three pipe hangers on both the supply and return of the pump be spring hangers. Flexible connectors should also be installed on the pump suction and discharge to isolate the pump from the piping.

Inertia bases and spring isolation should be sized by a seismic and vibration isolation consultant.

Grouting the Baseplate

Most manufacturers require that their based-mounted pumps be grouted installation on the pad. This involves filling the pump frame with a mixture of non-shrinking cement, sand, and water. The grout is poured into the pump base up to the top of the base rails to lock the pump base to the foundation. (Epoxy grouts, which cure faster, can also be used.) Not only does grouting further reduce vibration but the added stiffness helps maintain shaft alignment which reduces wear on the pump bearings and coupler.

Don't Forget the Drip Pan

If you are installing a pump that is being used on a chilled water application, make sure you have a drip pan installed under the pump volute to catch condensation as it drips off the pump. The pan should be piped to a drain to prevent wetting of the pump pad and surrounding floor.