How To Pick A Cooling Tower: Factoring Location Into Air Inlet Orientation

/By Chad Edmondson

Location, location, location. You know how important it is for real estate investments, but did you know it's also a critical factor when selecting the air inlet design for a cooling tower?

Proper (clean) air circulation around a cooling tower is essential to its performance and longevity. All of the following interfere with optimal air circulation and/or air intake:

- Locating a cooling tower with air inlets too close to a structural wall

- Locating a tower too close to any type of building exhaust

- Locating a tower too close to a building fresh air intake

- Locating a tower too close to an area that is prone to dust, debris or fuel exhaust

- Locating a tower so that the fan discharge is below the level of any adjacent walls or buildings

Any of the above can cause the air that circulates around the tower to be too moist, too warm and/or too dirty for proper operation.

When air inlets are located in close proximity to walls the circulation of air around the tower is impacted in ways that negatively impact performance. As shown in the above diagram, these design errors can cause warm moist air to circulate around the tower, increasing the wet bulb and thus interfering with the evaporative performance of the tower. This will lead to a decrease in performance and an increase in operating cost.

Locating a tower near a dirty air source or exhaust is also a problem. This can lead to excessive fouling of the heat transfer surfaces or corrosion of the tower and other pieces of equipment which can greatly shorten the life of a very expensive piece of equipment.

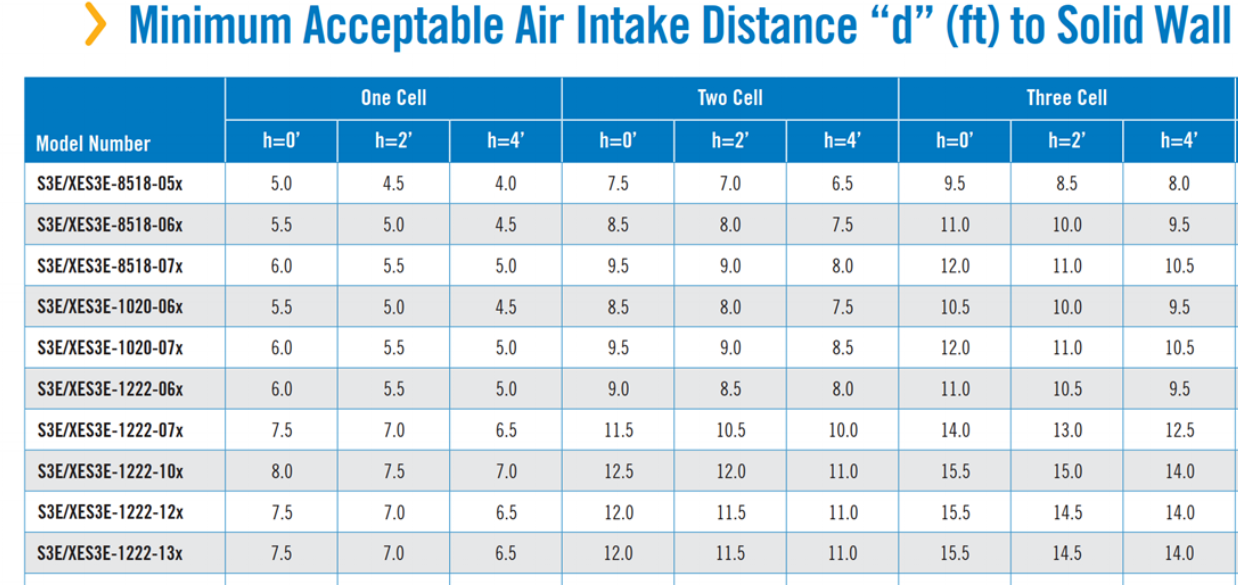

The following diagram and chart below defines the “d” value (or minimum air intake distance) required for a dual air inlet crossflow cooling tower configuration. All manufacturers of cooling tower equipment make this information available. Minimum distances are also listed by the International Building Code (IBC) as well as the Cooling Technology Institute (CTI).

Elevation view of a Dual Air Intake Unit Adjacent to Wall. See chart below for "d" values.

Distances required to meet certified performance.

Picking the Right Air Inlet Design and Orientation

Fortunately, cooling towers are available with a variety of air inlet designs that make them adaptable to many situations. Engineers can select any of the following configurations to ensure proper airflow around the tower while also achieving the desired capacity:

Obviously, a tower with air inlets on all four sides will require the most perimeter space for airflow. A single or dual air inlet tower, however, only requires minimum distance on one or two sides and can be can be positioned so that only the un-louvered side or sides(s) face any walls that are closer than the minimum required distance.

If the cooling tower must be surrounded by walls (perhaps the owner is adamant that it be hidden from sight) a wall with openings can be designed to help ensure sufficient airflow.

The take-home here is to remember that you have options, even when the available footprint is limited. Most importantly, engineers must provide for ample airflow to the cooling tower. Improper airflow completely undermines the very purpose of the cooling tower, which is maximum evaporative cooling.

For more on cooling tower air flow design, please refer to this previously published article: Cooling Tower and Condenser Water Design Part 4: Cooling Tower Air Flow Considerations.