Energy Efficient Hot Water Boiler Plant Design Part 6: Best Applications for Condensing Boilers

/By Chad Edmondson

Condensing boiler applications dovetail nicely with most of today’s energy efficient HVAC strategies, as well as ASHRAE 90.1 – 2010 and 2013 requirements. New and existing boiler plants are ripe with opportunities for condensing technology and can offer payback in as little as 2-3 years.

Here we’ve listed some of the top applications for condensing boilers and why they are a good choice in each situation.

Water Source Heat Pumps (WSHP)

WSHPs have become the “go-to” solution for many multi-tenant applications, as well as new multi-zone school designs. WSHP take advantage of the heating and cooling requirements of each space in the entire building by recovering otherwise wasted energy in some spaces and utilizing it elsewhere in the system. Such systems are comprised of highly efficient packaged reverse cycle heat pump units interconnected by way of a water loop. Each unit satisfies the air comfort requirements of its corresponding zone. In cold weather, the heat pump removes heat from the water loop via the unit's refrigerant-to-water coaxial heat exchanger and transfers it to the air. Excess heat is rejected via either a cooling tower or a closed-circuit cooler.

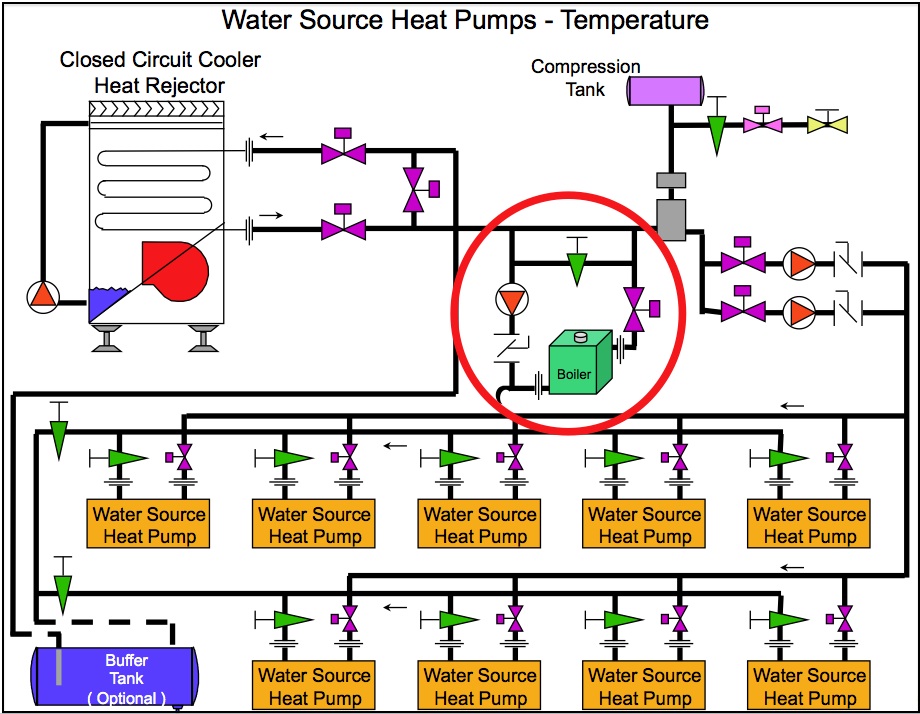

Because WSHPs operate at low temperatures, typically 60 to 90 degrees, they are ideal for use with condensing boilers. They not only operate more efficiently, they are not susceptible to the same maintenance issues as non-condensing boilers in the same WSHP applications. We have seen many WSHPs installed with traditional non-condensing boilers that are plagued with maintenance issues because the lower temperature water produced by the heat pumps causes condensation in the boilers. The only way to make this work is to install a bypass line with either a circuit setter or thermostatic control valve between the heat rejector and the boiler (Figure 1) that allows boiler supply water to mix with boiler return water to keep it above 130 degrees.

It’s simpler and more efficient to install a condensing boiler and take advantage of the low return water temperature. WSHP not only operate at ideally low temperatures, they are almost always operating at part load, which further enhances the efficiency of a condensing boiler.

Figure 1

This system does not have a condensing boiler – but it should! Notice the bypass line located between the supply and return line to the boiler. This is a necessary complication for non-condensing boilers used in WSHP applications. The bypass line is necessary to mix hot supply water with return water in order to keep it above condensing temperatures.Hydronic Heating with Outside Air Reset

Many hydronic heating (and cooling) systems incorporate temperature reset as a means to save energy. In fact, reset is now a requirement of ASHRAE 90.1 – 2010 and 2013. The only exceptions are when the application of reset interferes with the operation of heating, cooling, humidifying or dehumidifying systems, or variable flow pumping is used as an alternative method to save energy.

Systems with temperature reset are excellent application for condensing boilers.

While these systems may be designed to supply 180-degree water, reset control means that they will be frequently be operating below 180 degrees. Consider what happens when the temperature outdoors reaches 50 degrees during the heating season, as it frequently does in our own southeastern part of the country. Under these conditions the system will automatically reset according to a specified schedule, probably down to around 130 degree supply water. By the time that water makes it back to the boiler, it’s probably going to be 110 or 120 degrees – well below condensing threshold. That’s a problem with non-condensing boilers, but great news if condensing boilers have been used. With condensing boilers there’s no need to install any extra piping or valves to protect the boiler from the low temperature water. Moreover, condensing boilers will operate more efficiently at part-load conditions.

Hybrid Solution for Reset System Retrofits

A single condensing boiler retrofit is a perfect solution for a system that currently incorporates two or more non-condensing boilers operating on a reset schedule. In all likelihood the system is already experiencing maintenance issues due to rain in the boilers. Replacing just one of the non-condensing boilers with a condensing boiler increases efficiency of the system and eliminates these maintenance issues. The condensing boiler would be set up as the lead boiler and would operate all time, usually at part load conditions. (Figure 2) The only time the other boiler(s) would come on is when outdoor air temperature reaches peak conditions and the supply water temperatures would be above 160 or so.

Figure 2

This “hybridized” solution has relatively low upfront cost with excellent potential for payback and reduced maintenance.

Dual Temperature or “2-Pipe” Systems

There was a time when HVAC systems were designed to heat or cool with no in between. These very basic systems use a single set of pipes going out to the system and the water is either heated via the boiler or cooled by the chiller depending on the season. (Figure 3)

Figure 3

We still encounter these systems, and they are an excellent application for condensing boilers because they facilitate the transition time between heating and cooling mode. With non-condensing boilers, switching from heating to cooling or vice versa, is a tedious task that often takes a number of days. Time and care must be taken to avoid sending over-heated water to the chillers or cold water to the non-condensing boilers. However, if the boilers are designed for condensing, then you are mostly likely operating at lower temperatures while in heating mode, so you don’t have to wait as long (if at all) for the water to cool before you switch the chillers on. If you are switching from cooling mode to heating, there is no time lost, as the boilers will condense as they were designed and efficiency only gets better.

Radiant Heating Applications

Radiant heat applications, where there is hot water piping embedded in the concrete or just below the floor in a building, is another great application for condensing boilers. These systems typically operate within a range of 85 to 125 degree supply temperatures, thus they are always condensing and operate part load most of the time.

Click here to watch our YouTube video on Condensing Boiler Technology.

Download this document on Condensing & Non-Condensing Boilers/Water Heaters. This is a simple 2-Page "cheatsheet" that covers important topics like condensation, temperatures, venting, piping, and boiler materials.