Energy Efficient Hot Water Boiler Plant Design Part 2: Golden Rules of Condensing Boiler Technology

/By Chad Edmondson

Condensing boilers now dominate the new construction and replacement commercial markets. Here at JMP we estimate that as much as 90% of new boilers we sell are condensing boilers. So how did we get here and what is it about the technology that transformed the marketplace?

The trend toward condensing boilers has been evolutionary. It started with the introduction of atmospheric modulating non-condensing boilers. Modulating fire helped reduce fuel consumption, but because the chimneys still had to be sized for full air (since they were naturally drafted) a good bit of sensible heat, along with the hidden latent heat contained within the water vapor, was still lost up the chimney. These boilers tended to max out at efficiency around 82%.

Next came fan-assisted, non-condensing boilers. These boilers used a modulating fan to create the necessary air flow so that air could be controlled in a way that was proportional to the gas being supplied to the boiler at any given time. Less air lost up the chimney meant fewer Btus lost to the atmosphere. A side benefit of fan-assisted drafts was that flues could smaller, reducing a certain amount of material cost.

Then manufacturers began to really push the envelope on the efficiency of non-condensing boilers with other design improvements, including more efficient burners.

But none of these designs addressed the constant loss of latent heat contained within the water vapor that escaped the chimney. For gas boilers, that tended to be about 10% of the Btus it took to drive the boiler.

Additionally, none of these boilers could maintain peak efficiency unless they were at full load. At full load, efficiencies maxed out around 87 to 88%, and significantly dropped as the boiler modulated down. Any part load operation involved sacrificing efficiency – an unfortunate reality since full load design conditions are more the exception than the rule.

Finally, boiler manufacturers began to develop boilers with all the modulating components and build them so that they could safely condense and thus hold on to that elusive 10% of latent heat. It was great news for the industry, but some changes in design practice would also need to occur in order for these boilers to reach their 94-99% efficiency in the field.

We’re getting there. Condensing boilers are being applied in the field with great success these days, assuming everyone observes the two Golden Rules of condensing boiler operation:

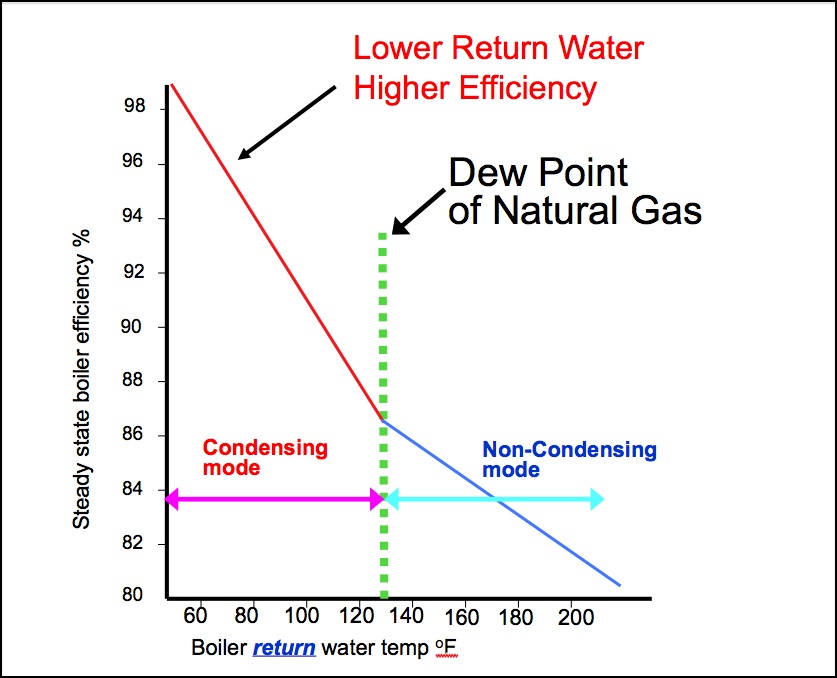

Rule #1: Condensing boilers must condense! If they aren’t condensing, then they are not retaining the latent heat of combustion. This means systems must be designed so that return water temperature is at least below 130. The lower the return water temperature the better the efficiency. Figure 1 shows just how dramatically return water temperature impacts the efficiency of a condensing boiler.

Figure 1

Rule #2: Condensing boilers are more efficient at part load! The reason for this is two-fold. As the boiler modulates toward low fire the heat exchanger capacity remains the same because the surface area has not changed. You’re still generating heat and your still condensing. As the fire rate increases, the amount of exhaust gas increases, which robs the boiler of some of its condensing capability.

With condensing boilers, the more you condense, the more efficient you are. That’s why two or three boilers at low fire are always better than one at full fire. Figure 2 shows how much efficiency is gained by operating condensing boilers at part load. As the graph shows, a condensing boiler at 25% fire is approximately 8% more efficient than when it is at 100% fire.

Figure 2

Figure 3 shows the combined effect of lowering return water temperature and part load operation on a condensing boiler.

Figure 3

Click here to watch our YouTube video on Condensing Boiler Technology.

Download this document on Condensing & Non-Condensing Boilers/Water Heaters. This is a simple 2-Page "cheatsheet" that covers important topics like condensation, temperatures, venting, piping, and boiler materials.